IIoT vs. IoT: What’s the difference and why it matters

Connecting devices to the internet has changed how we live and work. From wearable health trackers to smart factory sensors, connected systems let us automate tasks, share data, and make decisions faster.

This interconnected network is the foundation of both the Internet of Things (IoT) and the Industrial Internet of Things (IIoT). While these concepts are closely connected, they serve very different purposes.

In this guide, we’ll compare IoT and IIoT so you can easily see how they overlap, where they differ, and why those distinctions matter in real-world applications, security, and performance.

What is IoT?

The Internet of Things (IoT) is the network of physical items embedded with connectivity and intelligence that can exchange data and perform defined actions. These connected “things” help to automate tasks, improve efficiency, and create smarter environments in homes, cities, and businesses worldwide.

It encompasses both consumer- and industrial-oriented systems. The distinction between industrial IoT and consumer IoT lies in scale, reliability, complexity, and the operating environment.

What is IIoT?

Like IoT, the Industrial Internet of Things (IIoT) connects machines, sensors, and systems to collect and exchange real-time data, but it applies in industrial environments.

IIoT enables real-time monitoring of equipment health, predictive failure detection, and unprecedented precision in optimizing production. This is extremely important in environments where uptime, accuracy, and safety are critical.

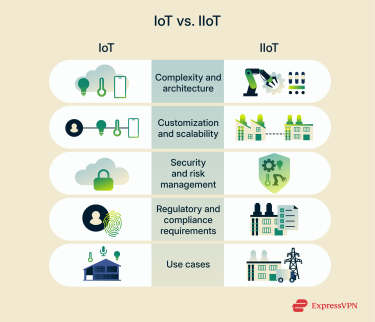

IIoT vs. IoT: 5 key differences

Both IoT and IIoT rely on connected devices and shared data infrastructure, but the differences between them go far beyond where they’re used.

Industrial systems have far stricter requirements; they must be faster, more reliable, and far more secure than everyday consumer devices. These demands create significant differences in how IoT vs. IIoT is built, how large they can scale, and what they’re ultimately designed to achieve.

1. Complexity and architecture

IoT systems generally connect a limited number of devices via simple networks (e.g., Wi-Fi or Bluetooth) that send data to the cloud for processing.

IIoT systems, on the other hand, operate at an entirely different level of complexity. They integrate thousands of sensors, machines, and control systems that must communicate in real time, often across multiple sites or facilities, to maintain uptime and precision.

For example, a smart home thermostat uses just a few sensors to adjust room temperature through a mobile app. The situation is more complex in an oil refinery, where thousands of industrial sensors are needed to monitor pressure, flow, and temperature, and feed data into the system.

2. Customization and scalability

The flexibility of IoT is intentionally limited. Most consumer systems are designed to work out of the box, offering preset functions that users can tweak but not rebuild. You can easily connect new devices, but each addition depends on the same cloud platform and standardized protocols. Beyond a certain point, performance and reliability start to decline.

Industrial systems work differently. IIoT deployments are highly customized from the start, explicitly built for the environment, equipment, and workflows they support. But once deployed, they offer far less adaptability; you generally can’t plug in new components or reconfigure the system without significant redesign.

3. Security and risk management

Security in IoT and IIoT differs less in principle than in practice. Consumer networks are usually isolated and cloud-managed so that a breach might expose data but rarely disrupt operations. In industrial environments, the same event can halt production or endanger lives.

For instance, a connected home camera might compromise your privacy if an attacker hacks into it, but a factory sensor network could shut down an entire assembly line.

That difference shapes how risk is managed. IIoT systems usually rely on layered protection, segmented networks, and constant monitoring. Access is tightly controlled, firmware updates are centrally managed, and every connected device must be verified before it can exchange data.

In IoT, security tends to be device-level. Users rely on default encryption, app permissions, and manufacturer updates to protect personal data.

4. Regulatory and compliance requirements

Everyday IoT devices can create legal responsibilities for users. For example, devices that record voice data or capture footage collect personally identifiable information about other people.

This activates privacy laws such as the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA). Manufacturers and users can both be held accountable for how that data is collected, processed, and shared.

In industrial environments, the picture shifts from privacy to compliance. IIoT systems generate operational data that can influence safety records, environmental reporting, and product traceability.

Manufacturers must demonstrate that connected systems comply with industry regulations, maintain accurate logs, and provide audit trails that demonstrate accountability. These requirements are often set by sector-specific standards or government regulators rather than consumer privacy laws.

5. Consumer vs. industrial use cases

IoT and IIoT both connect the physical and digital worlds, but they offer different value to end users. For consumers, IoT simplifies daily life by automating homes, tracking health, and improving personal convenience.

In industry, those same principles scale into systems that run entire operations. IIoT enables predictive maintenance, energy optimisation, and real-time control across factories, fleets, and infrastructure.

Everyday applications of IoT

We interact with IoT technology constantly, often without even noticing. It fits seamlessly into our routines, quietly automating tasks and improving comfort, safety, and efficiency.

Smart homes

Smart homes use connected devices to automate and manage household functions like lighting, temperature, security, and entertainment.

These systems rely on IoT technology to connect everyday appliances (think thermostats, cameras, speakers, and locks) to a shared network that can be controlled via an app or a voice assistant.

Sensors and microcontrollers gather data on motion, occupancy, and air quality, sending it to a central hub or the cloud for processing. Based on that data, devices can act automatically, adjusting the temperature when you leave or turning off lights in empty rooms.

Wearables

Wearables are devices you wear on your body, such as smartwatches, fitness bands, and even smart clothing. These gadgets are fitted with sensors and processors and can connect to the internet.

They collect data about your movements, heart rate, or location, send it over a network, and use that information to give you insights that can help you act or respond to those conditions.

Beyond personal fitness, wearables are used in healthcare, workplace safety, and sports performance, helping people monitor their health more accurately, prevent potential issues early, and make informed lifestyle or medical decisions.

Connected vehicles

Connected vehicles are cars and trucks equipped with sensors, internet connectivity, and onboard processing that let them exchange data with other vehicles, infrastructure, and cloud systems.

These devices allow real-time monitoring of vehicle health, route conditions, and driving behavior. For example, a Ford Ranger equipped with FordPass Connect can send alerts about engine issues, tire pressure, and fuel levels straight to the driver’s phone. It can also receive live traffic updates, remote start commands, and over-the-air feature updates.

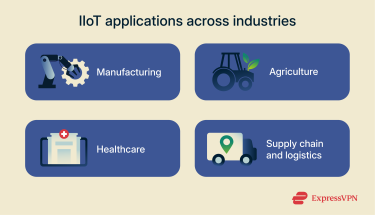

Common uses of IIoT

IIoT can be used in countless ways across different industries. By linking sensors, machines, and analytics systems, IIoT enables organizations to monitor operations in real time, improve efficiency, and make better decisions across a wide range of sectors.

Manufacturing automation

In the manufacturing sector, connected machines and robots share operational data across systems, allowing processes to self-optimize and adjust without human input.

Sensors track temperature, vibration, and energy use to detect inefficiencies or signs of wear before breakdowns occur. Real-time analytics support predictive maintenance, while edge computing enables faster, on-the-factory-floor decisions.

In automotive plants, for example, IIoT systems coordinate robotic arms to assemble vehicles with millimetre precision, while monitoring equipment health to prevent production stoppages. Food and beverage producers track equipment conditions and environmental factors such as humidity to maintain consistent product quality across batches.

Agriculture and smart farming

IIoT technologies can help farmers monitor crops, livestock, and equipment with greater precision, maximizing yield while minimizing resource consumption.

For crop farming, sensors placed in the soil track moisture, nutrient levels, and temperature, allowing irrigation systems to adjust automatically and conserve water. Drones and connected cameras survey fields in real time, identifying pests or crop stress before they spread.

In dairy farming, connected collars and tags track animal health and behaviour, alerting farmers to signs of illness early.

Healthcare systems

By linking medical devices, hospital systems, and patient data into a single network, IIoT enables doctors to access real-time information, supports medical staff with more coordinated tasks, and delivers faster, more accurate patient care.

For example, a patient’s wearable monitor can share data directly with hospital databases, while connected ambulances transmit vital information to emergency teams before arrival. Broader hospital maintenance systems track equipment performance and environmental conditions to ensure uninterrupted operation.

This level of interconnectivity not only improves diagnosis and treatment but also supports remote care models that keep patients safe and under continuous monitoring outside traditional clinical settings.

Supply chain and logistics

When shipments are in transit, sensors and GPS trackers provide a live view of where goods are, how they’re stored, and whether they’re on schedule.

Inside warehouses, connected robots, conveyor systems, and scanners share data to coordinate movement automatically and reduce handling errors. Fleet operators use the same data streams to predict maintenance needs, optimize delivery routes, and avoid costly delays.

The result is a logistics network that can adapt in real time to disruptions, rerouting shipments, reallocating resources, and maintaining continuity even when global conditions change.

Key benefits of IoT

By connecting devices and sharing real-time data, the IoT creates systems that are more efficient, intelligent, and responsive to human needs. The key benefits include:

- Efficiency: Automates repetitive processes and coordinates device communication to streamline daily tasks and reduce wasted time.

- Cost savings: Monitors usage patterns and operational performance to minimize energy consumption, maintenance costs, and resource inefficiencies.

- Personalization: Learns from user behaviour to tailor settings, responses, and services for a more seamless experience.

- Safety and security: Supports continuous monitoring that helps prevent accidents, breaches, or system failures before they escalate.

- Predictive maintenance: Uses real-time analytics to detect irregularities early, preventing breakdowns and prolonging equipment lifespan.

- Insightful decision-making: Transforms raw data into actionable intelligence, allowing individuals and businesses to make smarter, evidence-based decisions.

- Sustainability: Encourages more innovative use of energy and materials, reducing environmental impact through optimization and automation.

IIoT benefits

IIoT is driving a new era of efficiency, intelligence, and precision across industrial sectors. Connecting equipment, systems, and data, it enables organizations to operate smarter, safer, and with greater control over performance.

Here are some of the key benefits of IIoT implementation:

- Predictive maintenance: Detects early signs of equipment failure, reducing downtime and extending asset lifespan.

- Operational efficiency: Streamlines workflows and resource use through real-time monitoring and automated adjustments.

- Cost reduction: Lowers energy use, maintenance expenses, and material waste through smarter process management.

- Quality improvement: Ensures consistent product standards by tracking variables like temperature, pressure, and speed in real time.

- Worker safety: Monitors environmental conditions and machinery to prevent accidents and alert operators to potential hazards.

- Supply chain visibility: Tracks assets and materials from production to delivery to improve planning and reduce disruptions.

- Sustainability: Supports greener operations by optimising energy consumption and reducing emissions across production lines.

- Data-driven innovation: Uses analytics to uncover new efficiencies and business models that weren’t visible before.

Common mistakes when implementing IoT and IIoT

Implementing IoT and IIoT can offer significant advantages, but missteps during setup often hold these systems back.

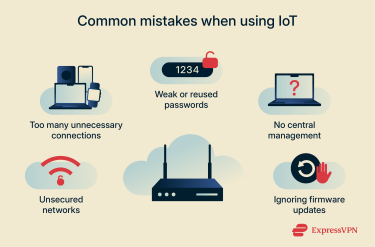

Network security

IoT

Consumer IoT devices often run on home networks that aren’t designed to support large numbers of connected devices. Weak Wi-Fi settings, outdated routers, or simply having too many devices online can create easy entry points for attackers. This is an example of the defender’s dilemma, where you must secure every entry point while an attacker only needs one. These vulnerabilities can expose personal data collected by smart home systems.

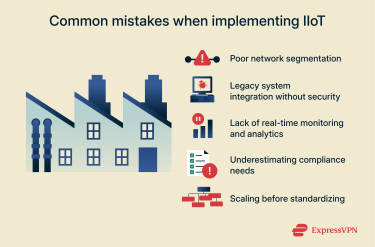

IIoT

In industrial settings, the stakes are much higher. When information technology (IT) and operational technology (OT) networks overlap, a single breach can quickly spread from administrative systems into production environments. Poor segmentation or outdated infrastructure can allow disruptions that affect critical equipment and operations.

Device and physical system security

IoT

Many home devices ship with limited security features, default passwords, or minimal protections. If these aren’t updated or changed, attackers can easily gain access and use one device as a stepping stone to others on the network.

IIoT

Industrial environments often rely on legacy machines that were never built with cybersecurity in mind. Connecting them directly to IIoT platforms can expose vulnerabilities such as unencrypted data, limited authentication, or insecure interfaces that are difficult to modernize.

Monitoring and visibility

IoT

As the number of home devices grows, it becomes difficult for users to keep track of what’s online, what’s outdated, or whether any unusual behavior is happening. Limited visibility can allow issues to go unnoticed for long periods.

IIoT

Industrial systems require continuous insight into large, distributed environments. Without real-time monitoring, warning signs of equipment failure, misconfigurations, or suspicious activity are easy to miss, leading to downtime or data issues across entire operations.

Software and firmware updates

IoT

Many users ignore or delay device updates, leaving older software versions active for months or years. Outdated firmware often contains known vulnerabilities that attackers can exploit.

IIoT

In industrial systems, update cycles are more complex, and organizations may postpone patches to avoid interrupting production. Over time, this increases the risk of unpatched vulnerabilities in critical equipment.

Standards and compliance

IoT

Most home ecosystems lack formal standards or consistent security practices. As devices from different brands are added, inconsistent configurations and mixed security levels become more common.

IIoT

Industrial environments must meet strict security and regulatory requirements, but these are sometimes overlooked during early deployment. Failing to align systems with established standards can create gaps in access control, patch management, and incident response.

System growth and scalability

IoT

Smart home setups often grow ad hoc, with new devices added without a broader plan. This can lead to cluttered networks and inconsistent settings, making long-term management difficult.

IIoT

Industrial systems face similar challenges but on a far larger scale. Expanding too quickly without standardizing data models, communication protocols, or operational standards leads to fragmented systems and unreliable information across sites.

How IIoT and IoT work together

While IoT and IIoT serve different purposes, they’re part of the same connected ecosystem. Data collected from everyday devices can feed into industrial systems, and insights from industrial networks can improve consumer applications.

They rely on standard communication protocols, like Message Queuing Telemetry Transport (MQTT) and HTTPS, and a combination of short- and long-range connections, such as Wi-Fi, Bluetooth, cellular, or Low-Power Wide-Area Network (LPWAN), to transmit data to cloud or edge platforms.

The key to this connection is interoperability: the ability of different devices, platforms, and networks to exchange and interpret data seamlessly.

Smart cities are one of the clearest examples of this intersection. In this context, data on traffic patterns generated by consumer-level IoT devices, such as connected vehicles and navigation systems, can be fed into IIoT systems that manage city infrastructure. Then, traffic signals and public transport routes can be adjusted to relieve congestion.

The same principle applies to energy management solutions. Data about household energy consumption patterns collected by smart thermostats and other connected appliances can be integrated into industrial grid systems.

Utilities then use IIoT analytics to balance load, forecast demand, and stabilise energy distribution in real time. This two-way exchange allows consumers to benefit from lower costs and greener energy use, while operators gain the insight needed to manage complex energy networks more effectively.

By connecting individual devices to industrial-scale systems, IoT and IIoT amplify each other’s impact.

FAQ: Common questions about IoT vs. IIoT

Is the Industrial Internet of Things (IIoT) just a part of the Internet of Things (IoT)?

Technically, yes. Both of these frameworks rely on technologies such as sensors and actuators, embedded processing and microcontrollers, cloud platforms and data analytics, and device identifiers to create interconnected systems. And they can work together to improve outcomes. However, where IoT focuses on individual consumers, IIoT is a subset of IoT designed to manage industrial systems.

How does IIoT improve manufacturing?

The main benefit of Industrial Internet of Things (IIoT) is that it gives manufacturers visibility into every stage of production. Sensors and analytics detect inefficiencies, predict equipment failures, and track product quality in real time. This reduces downtime, minimises waste, and helps factories run more efficiently and safely.

What are the 4 main types of IoT?

The four main types of the Internet of Things (IoT) can be grouped by application.

- Consumer IoT: Everyday connected devices like smart speakers, wearables, home appliances, and smart TVs.

- Industrial IoT: Sensors and machinery used in manufacturing, energy, logistics, and other industrial operations.

- Commercial IoT: Encompasses devices deployed in business environments, such as smart Heating, Ventilation, and Air Conditioning (HVAC) systems, security cameras, point-of-sale sensors, and building automation systems.

- Infrastructure IoT: Involves large-scale systems that support cities and public services, including smart grids, traffic management, environmental sensors, and utility monitoring.

How do Internet of Things (IoT) and Industrial IoT devices communicate?

To work together, IoT and IIoT use a mix of short- and long-range connections, like Wi-Fi, Bluetooth, cellular, or Low-Power Wide-Area Network (LPWAN), to share data with cloud or edge systems. Standard protocols, like Message Queuing Telemetry Transport (MQTT) and HTTPS, ensure that these devices can exchange information reliably across networks.

What are the security risks of using IoT devices?

Common Internet of Things (IoT) security risks include weak passwords, unpatched firmware, and unsecured networks. Attackers can exploit these to access personal data or control devices remotely. Using strong credentials, encrypting your internet connection, and regularly updating your devices can reduce these vulnerabilities.

Why is IIoT critical for modern industries?

Industrial Internet of Things (IIOT) benefits industries by bringing together data from various systems to help businesses anticipate problems, optimize production, and make faster, evidence-based decisions that improve safety, efficiency, and competitiveness.

How does IIoT enhance supply chain efficiency?

Industrial Internet of Things (IIoT) provides supply chain operators with real-time visibility across production, transport, and storage. Connected sensors track location, movement, and operating conditions, feeding continuous data into central logistics platforms so that teams can anticipate disruptions, optimize routing, and keep materials, components, and finished products moving smoothly.

Take the first step to protect yourself online. Try ExpressVPN risk-free.

Get ExpressVPN